Projects details

Powder Container & Mixers

Operating Cycle

The container with caster wheels is steered through the guide system provided below the main mixing head. This is a manual operation. Once positioned, it is raised high using lifting motors or jacks and secured tightly along the matching flanges with pneumatically operating toggle clamps.

The entire arrangement, mixing head, and container are rotated through 180° using a PLC automation circuit. Once the arrangement is correctly positioned at the 180° mark, the mixer starts, and the mixing cycle begins. The vortex generated ensures proper mixing of the components. Once the batch is completed, the equipment's mixing head returns to its original position, the pneumatic lock opens, and the lifting motor lowers the container back.

Additional Features: Water Jackets, Dust Extraction Nozzle, Temperature Controller.

Features

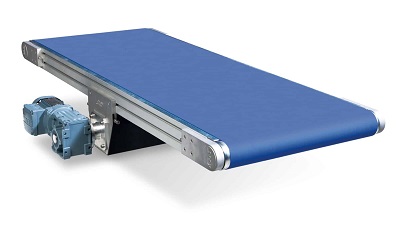

- The Endless Flat Belt Conveyor is coupled with a Squeeze Roller and Crusher system.

- Cooling achieved using SS nozzles. Water is sprinkled through solid cone spray nozzles mounted below the belt.

- The belt is covered with acrylic covers.

- The speed of the belt is controlled using a variable frequency drive.

Applications

- Chemicals

- Paint & Powder Coating

- Extrusion Machinery

- Dairy & Ice Cream

- Furnace & Foundry